Ambad, Nashik, Maharashtra

- GST NO. : 27AAAFY3001B1ZV

View Mobile Number

| Business Type | Manufacturer, Supplier |

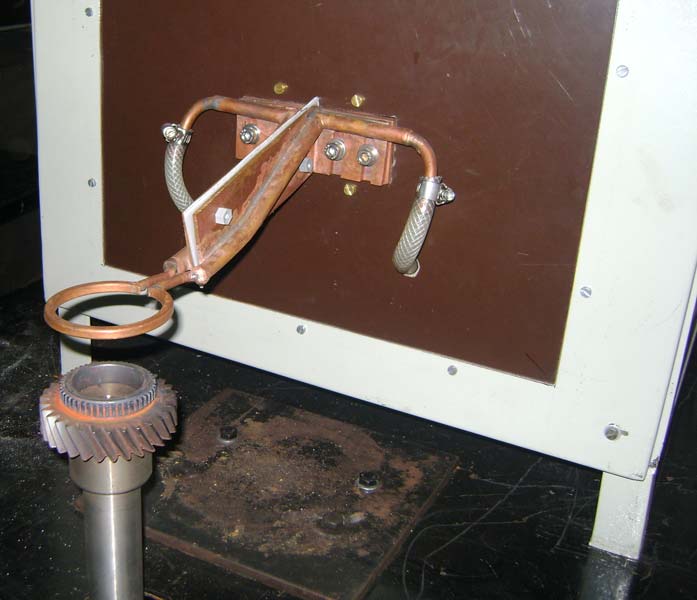

| Type | Induction Hardening Machine |

| Application | Hardening of Gears, Shaft, Pins |

| Weight | 100-1000kg |

| Click to view more | |

Product Details

Hardening is one of the main application areas. Thousands of our hardening solutions are at work around the world many of them within the automotive industry.  The main benefit of induction heating for hardening is that it takes just a few seconds. In a furnace, the same process can take hours or even days. How is that possible?  The answer is that induction is phenomenal at generating heat fast. This, in turn, means you can integrate hardening in the production process. Hardening in a furnace, on the other hand, is more time-consuming (greater heat loss) and requires moving the components either to your own furnace or to that of a sub-contractor.  In-line integration of hardening reduces your lead times considerably. You get full control over quality, delivery times and costs. There's no need to transport kilos of components back and forward, which saves energy and the environment. And last but not least, you cut down the amount of administration to a minimum.

Looking for "Induction Hardening Machine" ?

Explore More Products